Lovely!Just finished this rainshadow 7ft-6in, 4#. Found a great deal on these, so I brought 3 to get free shipping.Really enjoy finding attractive thread color combinations.

View attachment 106420View attachment 106422

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rod Building The Rod Building Thread

- Thread starter Divad

- Start date

Over in the Bamboo section, Mike Monsos showed how to clean up the epoxy edges using floss. I took his example and used a thick cotton thread on any sloppy borders I found. It works really well..

Last edited:

Divad

Whitefish

Currently working on this NFC Fast Glass (APFG) 742 for summer steelhead and beach coho. I’ve become addicted to the glass thing, so why not make a spinning rod with it. I extended 6.25” with an outer sleeve to help gain more backbone and speed up the rod a little.

I’ll throw together a write up when it’s all said and done to help with others searching topics such as how to sleeve an extension, KR Concept guide train and balancing tips. Was lucky to have a great mentor help me through this question filled build.

I’ll throw together a write up when it’s all said and done to help with others searching topics such as how to sleeve an extension, KR Concept guide train and balancing tips. Was lucky to have a great mentor help me through this question filled build.

Some nice work.View attachment 108215

Can’t decide on the large tapered end. It will feel better when two handing a cast, but does look a little different.

Divad

Whitefish

Thank you Porter. This is my first spinning grip, so debating on function over form.Some nice work.

I think I’ll take a little off the large end to make it less bulbous. It does feel good admittedly in its current form even if it looks a little goofy.

Bambooflyguy

Life of the Party

Looking good! And yes….I did make a bamboo spinning rod…..doesn’t get much use though.

Divad

Whitefish

Bamboo spinner sounds fun! I wiggled a bunch of rods at the NFC shop and this Medium Light S Glass blank felt very fun. Akin to a bamboo addiction.Looking good! And yes….I did make a bamboo spinning rod…..doesn’t get much use though.

Divad

Whitefish

Thank you Herk! I was going to be bummed if I botched it, so I calipered a lot and kept the strips of sand paper moving. Good to know about being careful with the hard/soft aspect, didn’t think of that…Nicely done. Sanding down rubberized cork (hard), next to burnt cork (soft) w/o leaving high/low spots can be difficult and you've done a perfect job.

Divad

Whitefish

Well you live and learn crash and burn, then you get back up and try again.

In order to get this grip to fit I have to ream to about 16mm. Since I didn’t have any rods thick enough I decided to wrap multiple strips on an old thick walled rod. I got a little impatient and instead of wrapping an even 4 layers of sand paper, I did 4 on half and then 2 on the other. The transition created too much of a step up on my reamer and cracked the grip halfway through.

So I went back and epoxied in the rest of the grip tape to an even taper.

These full length grips are tough on fat rod blanks, with a grip OD of 26mm and bore of 16mm you’re left with only 5mm per side. Definitely have to take your time.

In order to get this grip to fit I have to ream to about 16mm. Since I didn’t have any rods thick enough I decided to wrap multiple strips on an old thick walled rod. I got a little impatient and instead of wrapping an even 4 layers of sand paper, I did 4 on half and then 2 on the other. The transition created too much of a step up on my reamer and cracked the grip halfway through.

So I went back and epoxied in the rest of the grip tape to an even taper.

These full length grips are tough on fat rod blanks, with a grip OD of 26mm and bore of 16mm you’re left with only 5mm per side. Definitely have to take your time.

Paige

Wishing I was fishing the Sauk

Well you live and learn crash and burn, then you get back up and try again.

View attachment 108470

In order to get this grip to fit I have to ream to about 16mm. Since I didn’t have any rods thick enough I decided to wrap multiple strips on an old thick walled rod. I got a little impatient and instead of wrapping an even 4 layers of sand paper, I did 4 on half and then 2 on the other. The transition created too much of a step up on my reamer and cracked the grip halfway through.

So I went back and epoxied in the rest of the grip tape to an even taper.

View attachment 108471

These full length grips are tough on fat rod blanks, with a grip OD of 26mm and bore of 16mm you’re left with only 5mm per side. Definitely have to take your time.

I prefer to glue the rounds to the blank then shape it, alot easier IMHO.

Divad

Whitefish

To that tune, I’m sort of thinking I’ll ream it first to give more strength and then turn it with some tape arbors on the mandrel.I prefer to glue the rounds to the blank then shape it, alot easier IMHO.

Admittedly it was because of that reamer shortcut. It was tough to get the jump in diameter junction through the first half and the second half blew up. Well, lesson learned.

For longer (two-hander) grips, I prefer gluing them on the blank before turning, as they tend to flex while reaming and wind up as yours did. (Yours actually looks like it can be reglued and re-pressed). For larger dia blanks, I have stainless mandrills in various diameters to minimize the amount of reaming required. When reaming, I find an in/out/turn action is easier on the cork than spinning the reamer with a drill, which can generate heat, causing the glue to fail. BTW: No one taught me this..I learned by many failures....Hopefully this will save you the pain.....

Divad

Whitefish

It’s a 7’10” blank, and I don’t have the setup to turn such with cork on it. Interesting to think I could save this I might try that. I’ve already glued up a replacement to the threaded rod to try again. I do the hand turn thing as you mention already to prevent problems with centering. I 100% think it was my shortcutted reamer job. The drastic size jump junction required a lot of force to push it through.

Once the new one is dry I’ll take it off and see about epoxy and pressing the cracked grip. Then finish the ream process and if it holds up I’ll deem it acceptable to reuse. Didn’t even think I could reuse it so that would be nice, thank you!

Once the new one is dry I’ll take it off and see about epoxy and pressing the cracked grip. Then finish the ream process and if it holds up I’ll deem it acceptable to reuse. Didn’t even think I could reuse it so that would be nice, thank you!

I like Titebond III waterproof glue for gluing cork on a mandrill, as it sands easier and doesn't leave a glue line like epoxy does. I think it would be better for putting the grip back together.It’s a 7’10” blank, and I don’t have the setup to turn such with cork on it. Interesting to think I could save this I might try that. I’ve already glued up a replacement to the threaded rod to try again. I do the hand turn thing as you mention already to prevent problems with centering. I 100% think it was my shortcutted reamer job. The drastic size jump junction required a lot of force to push it through.

Once the new one is dry I’ll take it off and see about epoxy and pressing the cracked grip. Then finish the ream process and if it holds up I’ll deem it acceptable to reuse. Didn’t even think I could reuse it so that would be nice, thank you!

I use Rod Bond for gluing rings directly to the blank, as Titebond doesn't adhere to the blank as well.

Divad

Whitefish

Titebond is a little more enjoyable to work with anyways, thank you. I will give this repair job a go in a couple days. I'm glad I didnt get annoyed and shred the thing when it happened, just sort of chuckled as I felt it coming and should of fixed the reamer.I like Titebond III waterproof glue for gluing cork on a mandrill, as it sands easier and doesn't leave a glue line like epoxy does. I think it would be better for putting the grip back together.

I use Rod Bond for gluing rings directly to the blank, as Titebond doesn't adhere to the blank as well.

Worst case if my reamer doesn't smoothly transition up the taper this time I will stop immediately. Then check the hardware store if they have a bastard file large enough or order a large reamer from Mudhole. If I am impatient on shipping I can always pay ProLite Rods to ream it for me

Divad

Whitefish

Fly rod grips sure are a lot easier. I could also salvage that grip for a split grip too! I debated heavily on one of those from the start.

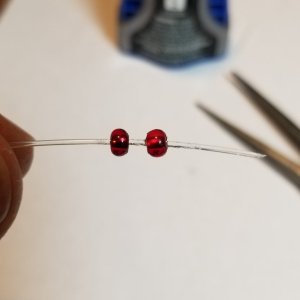

Side note I didnt like the butt plugs that a lot of the shops sell, so I found these metal buttons on Amazon and am going to inlay one into the hole at the bottom then coat in epoxy.

Side note I didnt like the butt plugs that a lot of the shops sell, so I found these metal buttons on Amazon and am going to inlay one into the hole at the bottom then coat in epoxy.

Love this idea..!Side note I didnt like the butt plugs that a lot of the shops sell, so I found these metal buttons on Amazon and am going to inlay one into the hole at the bottom then coat in epoxy.

View attachment 108485